Tires usually lose up to half their air pressure before they actually appear to casual observers to be low on air. Underinflated Tires have been found to underperform, leading to increased road accidents and fuel consumption.

As per the National Transportation Safety Board, US tires cause an average of 33,000 accidents each year. Around 2,000 of them are caused by blowouts.

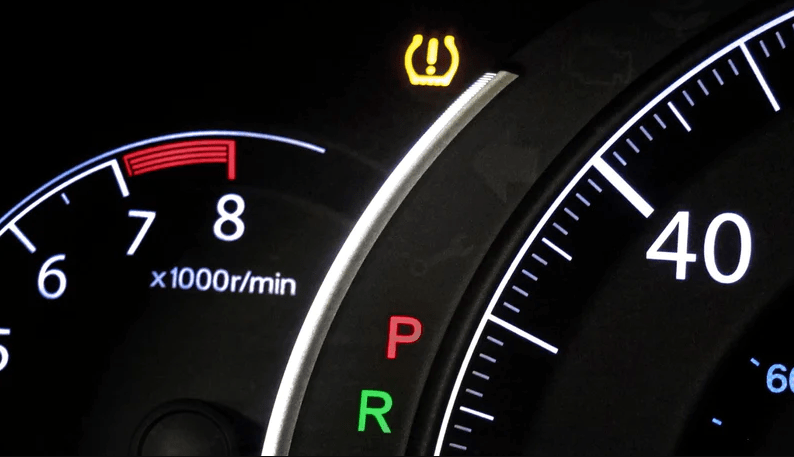

That’s why it’s so important to check your tire pressure regularly. And that’s how a tire pressure monitoring system (TPMS) positively affects users, by automatically alerting them when sensors detect a tire to be underinflated by 25% or more below the recommended tire pressure for the vehicle making driving safer than ever.

What is TPMS

Our basic understanding of the importance of TPMS for the automobile industry is already well established. Let’s now explore TPMS in more detail.

TPMS stands for Tire-pressure monitoring system is an electronic system in your vehicle that alerts the driver if the vehicle has punctured well before they have encountered a flat tire ensuring safety, efficiency, tire longevity, and overall vehicle performance.

What Technology does TPMS use?

The technology behind TPMS is a symphony of sensors, wireless communication, algorithms, and intelligent integration, all working harmoniously to ensure your Tires are in top-notch condition to make your vehicle hit the road in safer conditions and typically use two types of technology:

1. Direct TPMS:

It consists of small waterproof electronic hardware sensors that are fitted to each Tire of the vehicle that feeds the recorded data back to the car. As the electronic system observes the change in air pressure whether the data is underinflated or overinflated it shows a yellow warning light on the dashboard to alert the driver.

2. Indirect TPMS:

It involves leveraging existing vehicle systems with the help of software-based systems to keep a virtual eye on Tire pressure. Indirect TPMS relies on the antilock braking system (ABS), wheel speed sensors, accelerometers, and driveline data to estimate the Tire pressure data.

While indirect TPMS system are considered to be less accurate as compared to direct TPMS in detailing the exact level of pressure, they are still effective in detecting the changes in Tire pressure.

The Technology behind TPMS

You might be wondering how those little TPMS devices work wonders for your ride. Let’s take a look at the intricate process it went through to keep us safe on the road.

The following steps are involved in manufacturing and testing the TPMS structures:

1. Sensor Production: The heart of a TPMS is the MEMS pressure sensor. These sensors are often made using semiconductors and other electronic components. The manufacturing process involves assembling and testing these components to ensure accurate pressure measurements.

2. Battery Installation: Many TPMS sensors are powered by batteries. The installation of these batteries is a crucial step. Some sensors have replaceable batteries, while others have sealed units with a limited lifespan.

3. Housing Assembly: The tire sensors components are placed into a protective housing. This housing is designed to withstand the harsh conditions of the road, including exposure to various weather elements and potential physical damage.

4. Wireless Communication Module: TPMS sensors often communicate wirelessly with the vehicle’s central monitoring system. The manufacturing process includes integrating the necessary communication modules and ensuring they work seamlessly with the vehicle’s electronics.

5. Quality Control Testing: Each tire pressure system unit undergoes rigorous testing to ensure its accuracy and reliability. This may involve pressure testing, battery performance checks, and communication tests to guarantee that the sensor will function properly in real-world conditions.

6. Integration with Wheels or Tires: In some cases, TPMS sensors are integrated directly into the wheel or tire assembly during the manufacturing of these components. This integration can simplify the installation process for vehicle manufacturers.

From now on, remember to give due credit to tires that keep your vehicle rolling, mile after mile, always watching out for your safety.

Automotive Tire Pressure Monitoring System: Market Dynamics and Future Outlook

The demand for TPMS is hitting a continued surge fueling the industry’s growth. The global tire pressure monitoring system market is expected to reach US$ 7.7 Billion by 2032 as per future market insights.

To cite an instance, in May 2022, the introduction of a new EU regulation enforced the legal requirement of tire pressure system in light commercial vehicles, buses, trailers, and semi-trailers. This measure aims to decrease tire wear and enhance vehicle safety. Likewise, in Canada, approximately 70% of passenger cars and light trucks (model years 2007-2013) are equipped with TPMS. With the widespread adoption of TPMS globally, countries such as India, Japan, and China have also integrated this technology.

Another accelerating factor is the growing number of accidents caused by tire-related issues has further ensured the alarming need for proper tire pressure system and better fuel efficiency. The demand for tire pressure system is also driven by increased vehicle production growing awareness of vehicle safety and the increasing adoption of advanced driver assistance systems (ADAS).

Lifesaving Role People are receiving from TPMS.

Preventive maintenance through tire pressure monitoring systems provides road safety but other significant benefits:

1. Fuel Efficiency: Properly inflated tires reduce rolling resistance. Vehicles using tire pressure system consume less fuel, reducing both their environmental footprint and their fuel bill.

2. Tire Longevity: Proper Tire inflation leads to equal wear over the life of the tire. The tire will last longer as a result, ensuring the best return on your investment.

3. Reduced Maintenance Cost: By alerting drivers to potential tire issues, It aids in avoiding unexpected and potentially costly tire malfunctions or damages.

4. Environmental Impact: Tire pressure system not only saves you money but also reduces your carbon footprint. By optimizing tire pressure, that leads to lower fuel consumption and, consequently, lower emissions.

So in addition to keeping you safe on the road, TPMS system contributes to cost savings, environmental responsibility, and overall vehicle performance.

Leading automotive companies adopting TPMS technology

The automotive industry is no doubt changing rapidly. Given the global adoption of TPMS, vehicle manufacturers will continue to manufacture Tires for both the global & well as domestic markets with tire-pressure systems to take global advantage marking a pivotal shift in vehicle safety standards.

Major Players Leading Charge in TPMS

- Michelin

- Continental AG

- Goodyear

- Bridgestone

These companies are at the forefront of TPMS technology, ensuring that vehicles equipped with their systems adhere to the highest safety standards.

What’s next for the TPMS technology

From intelligent tiers to ever-evolving TPMS technology is on the brink of some exciting advancements. In, the last 10 years it went from an optional feature on new passenger vehicles to a mandatory one.

So what is next?

BLE TPMS:

Bluetooth Low Energy Tire Pressure Monitoring System ensures real-time tire pressure monitoring with minimal energy consumption and seamless connectivity, unlike traditional TPMS technology. This enables remote diagnostics, so that some repairs can be performed without the need to visit the shop.

How Napino Can Support?

TPMS has become an essential feature of every automobile on the road today to ensure safe driving. As an Electronics System Design and manufacturing (ESDM) provider, Napino Digital Solutions is dedicated to ensuring the seamless integration of Tire Pressure Monitoring System into vehicles worldwide through a range of comprehensive services.

1. Design and development: Napino takes pride in its innovative approach to design & developing Tire Pressure Monitoring System solutions. We have a team of 200+ creative minds to ensure robust and efficient TPMS systems tailored to meet each automotive manufacturer’s needs.

2. Prototyping: Napino Digital Solutions leads the way in rapid prototyping, by testing, trying, and accelerating the product prototype with unmatched speed and precision.

3. Manufacturing services: We provide a full- range of capabilities essential for producing high-quality BLE TPMS units. Napino’s high-speed precision lines ensure efficiency with precision from assembly to final inspection with strict adherence to international ISO standards, including IATF 16949:2016.

4. Test and validation lab services: Quality assurance is at Napino Digital Solution’s core. In our dedicated labs, rigorous testing protocols guarantee TPMS units functionality, and durability surpassing industry standards for real-world reliability.

As we conclude our exploration of Tire Pressure Monitoring System and its role in preventing tire blowouts and road accidents, let’s acknowledge the tire-pressure monitoring system technology —that tirelessly keeps our vehicles rolling mile after mile.