Globally, there is a strong trend toward outsourcing electronics manufacturing, to balance the production cost and transaction cost of manufacturing. For OEMs, this balance needs to be struck while also practicing due diligence. The general term applied here is XaaS, or Anything as a Service, which applies to any service that can be provided to a customer by a commercial partner. For OEMs, this broad scope can be focused on Electronics Manufacturing Services in India. The nature of a global market means that all vertical sectors operating in multiple regions are subject to variable economic pressures. Locally, those pressure may be quite different but, collectively, they will influence business decisions.

In October 2020, India’s Ministry of Electronics and IT (MeitY) approved the applications from ten international mobile phone manufacturers for a share of its Product Linked Incentive scheme, including Samsung, Foxconn Hon Hai, Rising Star, Wistron, and Pegatron. In August 2020, Samsung Electronics Co and Apple Inc collectively pledged nearly $1.5 billion of investment to establish mobile phone manufacturing units in India. These investments, both from international companies and India’s government, show the commitment to making India’s Electronic System Design and Manufacturing (ESDM) sector stronger and demonstrate the financial benefits of investing in India.

Original electronics manufacturers in India looking to outsource electronics manufacturing must look closely at potential ESDM partners. This includes requesting details about the electronic manufacturing service provider’s capacity, capabilities, and accreditations, of course, but it also extends to the stability and support they receive from their parent nation.

In India, the government in the past has approved a scheme to support electronics manufacturers in India operating in 10 key sectors. The funding is intended to help make India more competitive on a global scale, but ultimately it also helps those companies advance and maintains the services they offer to their OEM customers. This five-year plan builds on a long history of development in the region.

With a strong design and electronics manufacturing infrastructure already in place across India, Napino Digital Solutions is an established supplier in this respect and is well-positioned to leverage the scheme for itself and its clients.

As an example, the automotive manufacturing sector in India has evolved over the last seven decades, from a net consumer to a resource for final assembly, and more recently into a global provider of outsourced electronics manufacturing services. To maximize the efficacy of outsourcing, OEMs should consider how much of the process they can outsource. For electronic products, this covers the design, manufacture, test, certification, and validation processes.

Unlocking India’s Electronics Potential: A Roadmap to Success

- Why does India make a good choice for electronic manufacturing as a service?

- A Dynamic Consumer Demand for Electronic Manufacturing Services in India.

- A manufacturer’s perspective on electronics.

- Making electronics manufacturing services in India more efficient through IoT.

- Take your product to mass production with Napino Digital Solutions.

What makes electronic manufacturing as a service in India a smart choice?

No doubt, India is a smart choice for outsourcing electronic manufacturing. With its impressive infrastructure and skilled workforce, India offers numerous advantages. According to a report by Counterpoint more than 2 billion mobile phone manufacturing units set up on its soil, India has established itself as a significant player in the electronics manufacturing industry. And it’s not just mobile phones – India also excels in other segments like consumer electronics, IT hardware, and electronic components. Clearly, This shows the diversity and strength of the Indian electronic manufacturing ecosystem.

Now let’s deep dive into why India is a smart choice for electronics manufacturing

- Skilled Workforce: One of the key factors that make India a smart choice is its skilled workforce. The country is known for its strong engineering and technical education system, producing a large number of talented professionals every year. This ensures that companies can find the right talent easily and reduce their training costs.

- Seamless Global Connectivity: India’s strategic location offers easy access to major global markets. It serves as a gateway to other Asian countries and contributes to the efficient movement of goods and information, fostering a seamless flow of commerce and communication across continents.

- Thriving R&D Ecosystem: The major factor that makes India a smart choice for electronic manufacturing outsourcing is its strong ecosystem for innovation, research, and development. The country has made significant investments in R&D, resulting in state-of-the-art facilities and cutting-edge technologies.

- Cost-effectiveness: India’s favorable labor costs and operational expenses make it an economically attractive destination for electronic manufacturing to other countries. This advantage enables companies to optimize their production budgets while maintaining high-quality standards.

- Supply Chain Integration: India’s electronic manufacturing ecosystem seamlessly integrates with global supply chains, offering companies efficient access to raw materials, components, and resources. This integration enhances production efficiency and reduces lead times.

- Government Initiatives: The country’s favorable government policies and incentives for the electronics industry such as Make in India & Digital India have played a crucial role in promoting domestic manufacturing and encouraging foreign investment. These policies provide tax benefits, subsidies, and easier regulatory processes for companies engaged in electronic manufacturing services.

Needless to say, India’s skilled workforce, advanced infrastructure, and business-friendly environment make it an ideal choice for electronic outsourcing services worldwide.

Electronic Manufacturing Services In India: Adapting To Dynamic Consumer Demands

The world of consumer electronics is constantly evolving, and with it, so are the preferences and demands of customers.

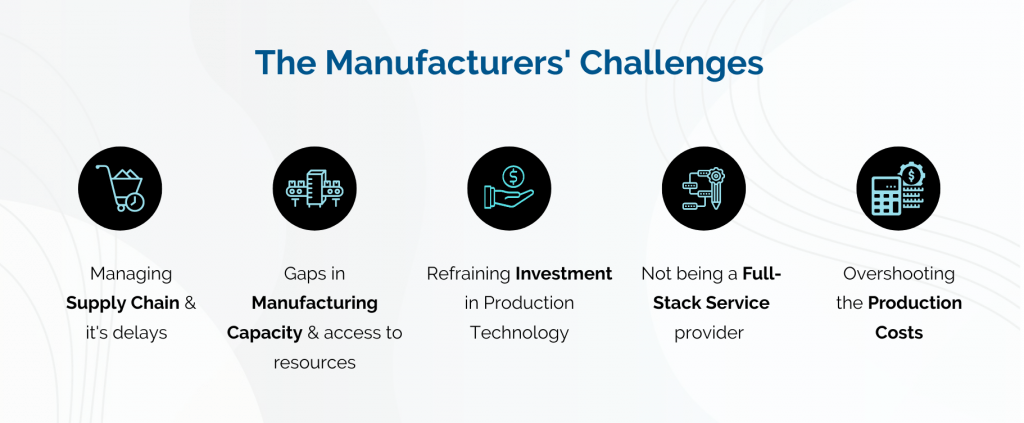

Delve into Manufacturing challenges in 2023 and how EMS providers are overcoming them:

- Product Customization: Today’s consumers are seeking more than just standard, off-the-shelf products – they want something that is uniquely tailored to their needs and preferences. This demand for customized products has significantly influenced the strategies of electronics manufacturing companies, forcing them to adapt to manufacturing challenges in 2023 to stay competitive in the market.

- Accelerating Delivery Demands: In addition to customization, another important aspect of changing consumer preferences is the need for faster delivery. The customers expect their products to be delivered to them as quickly as possible. This need for speed has forced consumer electronics manufacturers to rethink their supply chain strategies and find ways to expedite the delivery process.

The changing consumer preferences for customized products and faster delivery have greatly influenced the strategies of consumer electronics manufacturers. Napino Digital Solutions have recognized these trends and have successfully adapted to meet these demands with there innovative strategies. By offering a range of customization options and optimizing its supply chain.

The scope for Electronics manufacturers

Deciding on your electronic manufacturing service provider for any activity requires careful consideration. The challenges here are many, but it is the nature of electronic products to comprise hundreds of individual components. Each one of those components will have a critical role, from the largest integrated circuit to the simplest passive component.

Managing the supply chain for the Bill of Materials is fundamental when working to a customer’s schedule. This requires an electronics manufacturer that can demonstrate a world-class procurement system, with access to leading component suppliers and robust logistic networks.

Any delay in the supply of any component can have a compounding impact on delivery times, so the ability to demonstrate a well-developed and proven JIT (Just in Time) approach to manufacturing is non-negotiable. Equally important is the partner’s capacity, expertise, and access to the resources needed to deliver a world-class service. In a manufacturing environment, this can be demonstrated by inspecting the manufacturing facilities, including the equipment needed for PCB assembly, flow soldering, inspection, and final assembly. The investment required to establish these resources is considerable.

Napino Digital Solutions is not alone in making huge investments in its production technology, for the implementation of Industry 4.0. This enables it to fully support any global standard, at any scale.

For a full, turn-key service, OEMs will also be looking for partners that can provide value-added services, such as design evaluation. This may involve consultation that assesses the readiness of a design from a DFM (Design for Manufacture) point of view. The production costs of outsourcing electronics manufacturing in India are largely dependent on the electronic manufacturing service provider’s capabilities and this very much extends to their ability to carry out a DFM analysis. The OEM customer should not pay for the lack of manufacturability if the services partner isn’t able to help identify issues early on in the relationship.

Utilizing IoT to overcome challenges in electronics manufacturing

There is a major evolution happening in electronics manufacturing, with the adoption of IoT technologies in what is generally referred to as Industry 4.0. This enables manufacturing data, generated on the production line, to contribute towards a more effective process. Companies embracing Industry 4.0 need to invest in new systems that support this Big Data paradigm. They must also have a well-defined strategic approach to using that data most effectively. The returns on this investment are transferred directly to the customer, who receives a better service at a more competitive price.

This requires a manufacturing execution system (MES) that brings together all key elements; a smart supply chain with smart services, and smart innovation to deliver smart products. This vertical and horizontal integration of services and capabilities delivers smart manufacturing on a scale that reflects the needs of a global economy.

Modern manufacturing equipment is equipped with Industry 4.0 connectivity, but it takes a leading-edge MES to bring that together in a way that delivers real value. It means components and products are monitored and traced at every step in the production process. Operators work with the equipment to ensure customer lines operate in an optimized flow.

Partner with Napino Digital Solutions to take your product to the mass manufacturing stage

Outsourcing electronic manufacturing services is a growing trend. Analysts estimate the sector is already worth over $400 billion. This puts electronics manufacturing services providers in a strong economic position to drive the cost up. India is emerging as a financially viable destination for outsourced electronic manufacturing services, thanks to the global conditions now in force. Succeeding in a global arena demands a provider that can demonstrate it has already made the necessary investments in its infrastructure and can offer contract manufacturing services. Electronics contract manufacturing companies in India like Napino Digital Solutions has demonstrated this and has the economy of scale needed to be responsive but still agile.

It also requires demonstrable expertise in the specific application areas and vertical sectors targeted. Like Napino, the ESDM must also embrace the latest technology to achieve high efficiency and exemplary supply chain management. Operating a production line is only part of the solution. A reliable electronics manufacturer also depends on excellence at the design stage, expertise in PCB assembly, an ability to manage the entire product lifecycle, and an investment in the very best quality assurance and inspection technologies, to maximize yield.

Napino is one of India’s leading manufacturers of electronic assemblies, with a strong reputation and established relationships with leading OEMs around the world. As a technology-driven organization, it has sustained its growth through business excellence. As part of its mission, Napino Digital Solutions continuously strengthens and upgrades its manufacturing processes and quality systems, while investing in its employees.

This has enabled Napino Digital Solutions to become the leading electric/electronics manufacturer in India with more than 20 million units manufactured annually. With seven manufacturing sites and two R&D/Design Centers, Napino Digital Solutions counts many leading Tier 1 and Tier 2 suppliers as customers.

CONCLUSION

Manufacturing electronics & the global need for excellence in electronic product design outweigh availability. More OEMs are now looking to focus on their core skills to bring more products to market faster, to meet consumer demand. India is emerging as the most competitive destination for outsourced Electronic manufacturing services providers in India. With its long history of excellence, demonstrable investment in technology and people, and a commitment to exemplary customer service,Napino Digital Solutionsis already working with many of the world’s leading automotive, consumer goods, and medical OEMs. Its mission remains to deliver the best range of electronics manufacturing services in India, from design, production, test, assembly, and certification.