Electric vehicles are no longer seen as luxury items. While a high cost can create exclusivity, EVs have moved into the mainstream and must now be priced accordingly. Of course, exclusivity is also aspirational, so this has also contributed to increased demand. EV manufacturers must now set their selling price right, to meet the increased demand. If not, they risk missing out on the wave of prosperity.

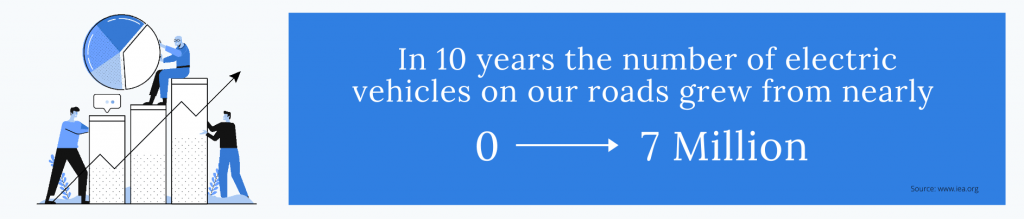

Huge opportunities now exist for electric vehicle manufacturers. The EV wave continues to build, which will see demand and the sales of battery electric vehicles (BEVs), hybrid electric vehicles (HEVs) and plug-in hybrids (PHEVs) increase over the next several years.

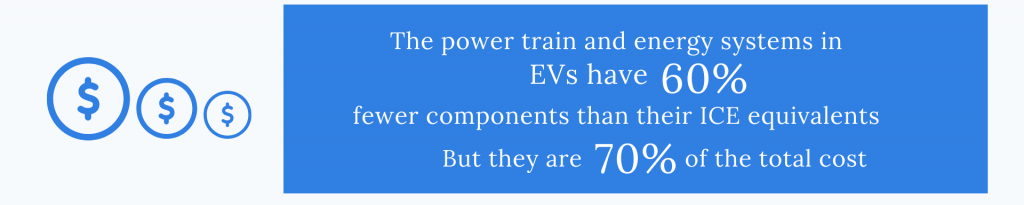

Unlike other exclusive or luxury goods, the price of EVs are not artificially high. It costs a lot to design and manufacture an EV. Cost optimization is critical in the life-cycle of any product and the same is true for EVs. The challenge EV manufacturers face is in cost-optimizing their designs.

This is where Napino can help. It can be difficult for new entrants into the EV market to compete on price, particularly if they do not have access to the best supplier opportunities. Napino has teams of engineers ready to cost-optimize key parts of an EV design. That may mean finding an alternative supplier or negotiating better terms with an existing supplier. It may also involve redesigning part of the system or developing a more cost-effective production process.

We are already past the ‘early adopter’ stage, where consumers are willing to pay a premium to be the first to own a product. We are now well into the mass adoption phase, where more familiar economics come into play. This means selling price has become one of the most important factors considered by potential consumers.

Customer demand is influenced by changes in price. Often, demand increases as price decreases. Price elasticity of supply is arguably more complicated, as it relates to tangible costs. This includes the cost of components, the cost of production and assembly, and the cost of support.

Getting the right balance in terms of cost and price is the job of a Chief Financial Officer and accountants, as well as engineers. Selling prices can be tweaked in order to optimize sales, but only while still meeting cost targets on the supply side. This is crucial to providing any amount of flexibility in selling price.

Read More: Developing a World Wide Ecosystem for E-Mobility (White Paper)